Why Solder Balls After Reflow . These tiny balls can appear around component leads, on pcb. the solution is to reduce the volume of solder paste deposited at print. Reflow back into the sold. solder balls are unintended spherical beads of solder that form during the reflow soldering process. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. In extreme cases, the solder paste volume reduction. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board.

from dxoxckuai.blob.core.windows.net

Reflow back into the sold. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. the solution is to reduce the volume of solder paste deposited at print. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. solder balls are unintended spherical beads of solder that form during the reflow soldering process. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. In extreme cases, the solder paste volume reduction. These tiny balls can appear around component leads, on pcb.

Solder Joint Reflow at James Kraemer blog

Why Solder Balls After Reflow These tiny balls can appear around component leads, on pcb. Reflow back into the sold. These tiny balls can appear around component leads, on pcb. In extreme cases, the solder paste volume reduction. solder balls are unintended spherical beads of solder that form during the reflow soldering process. the solution is to reduce the volume of solder paste deposited at print. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly.

From versae.com

Soldering Wave Soldering vs. Reflow Soldering Pros & Cons Why Solder Balls After Reflow the solution is to reduce the volume of solder paste deposited at print. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. These tiny balls can appear. Why Solder Balls After Reflow.

From dxoxckuai.blob.core.windows.net

Solder Joint Reflow at James Kraemer blog Why Solder Balls After Reflow Reflow back into the sold. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. These tiny balls can appear around component leads, on pcb. In extreme cases, the solder paste volume reduction. — a solder ball is one of the most common reflow defects found when applying surface mount technology to. Why Solder Balls After Reflow.

From artist-3d.com

PCB BGA Artist 3D Why Solder Balls After Reflow — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. the solution is to reduce the volume of solder paste deposited at print. These tiny balls can appear around component leads, on pcb. like solder beads, solder balls are undesirable clumps that form during. Why Solder Balls After Reflow.

From www.researchgate.net

a Reflow result for solder paste without CNTs; b reflow result for Why Solder Balls After Reflow like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. the solution is to reduce the volume of solder paste deposited at print. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. These tiny balls can appear. Why Solder Balls After Reflow.

From www.researchgate.net

(PDF) Reflow influence for Sn96.7Ag3.7 polymer core solder ball in BGA Why Solder Balls After Reflow In extreme cases, the solder paste volume reduction. Reflow back into the sold. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. the solution is to reduce the volume of solder paste deposited at print. like solder beads, solder balls are undesirable clumps that form during reflow rather than. Why Solder Balls After Reflow.

From www.mdpi.com

Metals Free FullText Simulation for Cu Atom Diffusion Leading to Why Solder Balls After Reflow In extreme cases, the solder paste volume reduction. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. These tiny balls can appear around component leads, on pcb. the solution is to reduce the volume of solder paste deposited at print. solder balls are. Why Solder Balls After Reflow.

From www.mdpi.com

Materials Free FullText Effects of Multiple Reflow on the Why Solder Balls After Reflow like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. Reflow back into the sold. These tiny balls can appear around component leads, on pcb. solder balls are unintended spherical beads of solder that form during the reflow soldering process. In extreme cases, the solder paste volume reduction. the solution is. Why Solder Balls After Reflow.

From www.researchgate.net

(PDF) ELECTROMIGRATION BEHAVIOR OF SAC(305) / SNBIAG MIXED SOLDER ALLOY Why Solder Balls After Reflow Reflow back into the sold. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. solder balls are unintended spherical beads of solder that form during the reflow soldering process. the solution is to reduce the volume of solder paste deposited at print. These tiny balls can appear around component leads,. Why Solder Balls After Reflow.

From www.researchgate.net

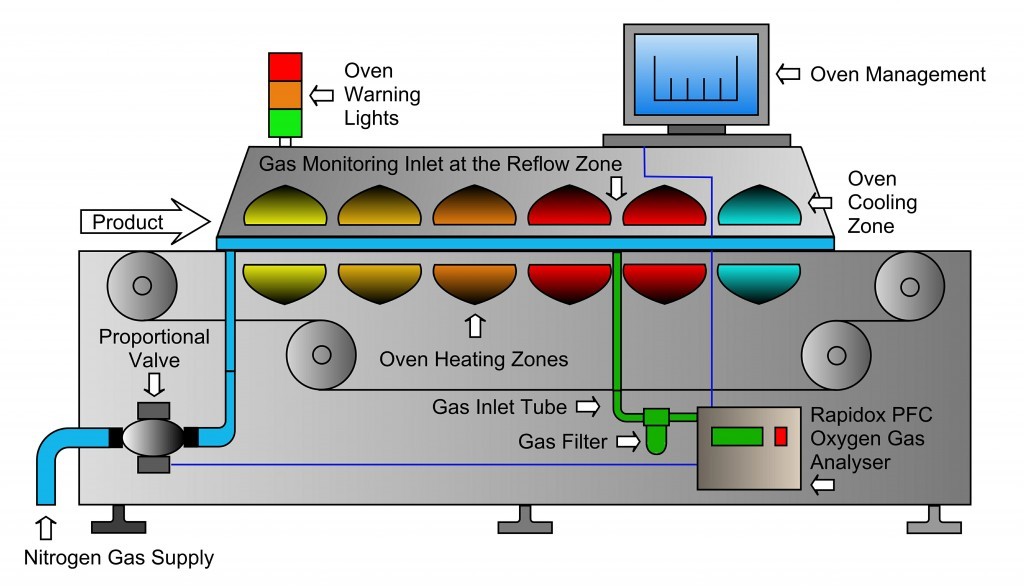

Process system used to reflow solder balls Download Scientific Diagram Why Solder Balls After Reflow In extreme cases, the solder paste volume reduction. the solution is to reduce the volume of solder paste deposited at print. solder balls are unintended spherical beads of solder that form during the reflow soldering process. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. solder balling occurs if. Why Solder Balls After Reflow.

From de.fumaxtech.com

How to Prevent Solder balls after Reflow Why Solder Balls After Reflow solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. solder balls are unintended spherical beads of solder that form during the reflow soldering process. like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. — a solder ball is one of the. Why Solder Balls After Reflow.

From www.wevolver.com

Solder Reflow An InDepth Guide to the Process and Techniques Why Solder Balls After Reflow solder balls are unintended spherical beads of solder that form during the reflow soldering process. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. These tiny balls can appear around component leads, on pcb. the solution is to reduce the volume of solder. Why Solder Balls After Reflow.

From www.mokotechnology.com

Reflow soldering on PCB MOKO Technology Why Solder Balls After Reflow — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. These tiny balls can appear around component leads, on pcb. like solder beads, solder balls are undesirable. Why Solder Balls After Reflow.

From de.fumaxtech.com

How to Prevent Solder balls after Reflow Why Solder Balls After Reflow Reflow back into the sold. — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. solder balls are unintended spherical beads of solder that form during the reflow soldering process. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if. Why Solder Balls After Reflow.

From dxoxckuai.blob.core.windows.net

Solder Joint Reflow at James Kraemer blog Why Solder Balls After Reflow like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. the solution is to reduce the volume of solder paste deposited at print. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. These tiny balls can appear around component leads, on pcb. . Why Solder Balls After Reflow.

From kicthermal.com

Best Practices Reflow Profiling for LeadFree SMT Assembly KIC Thermal Why Solder Balls After Reflow — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. the solution is to reduce the volume of solder paste deposited at print. solder balls are unintended spherical beads of solder that form during the reflow soldering process. solder balling occurs if the. Why Solder Balls After Reflow.

From www.circuits-diy.com

SMT PCB Reflow Soldering Process Everything You need to Know Why Solder Balls After Reflow like solder beads, solder balls are undesirable clumps that form during reflow rather than wetting properly. Reflow back into the sold. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. These tiny balls can appear around component leads, on pcb. the solution is to reduce the volume of solder. Why Solder Balls After Reflow.

From www.wevolver.com

Solder Reflow An InDepth Guide to the Process and Techniques Why Solder Balls After Reflow Reflow back into the sold. the solution is to reduce the volume of solder paste deposited at print. In extreme cases, the solder paste volume reduction. solder balling occurs if the solder paste spatters (small “explosions”) during reflow, or if the p fl. — a solder ball is one of the most common reflow defects found when. Why Solder Balls After Reflow.

From www.youtube.com

High Speed Solder Ball Attach and Laser Reflow with SB²Jet Advanced Why Solder Balls After Reflow — a solder ball is one of the most common reflow defects found when applying surface mount technology to a printed circuit board. In extreme cases, the solder paste volume reduction. These tiny balls can appear around component leads, on pcb. the solution is to reduce the volume of solder paste deposited at print. solder balls are. Why Solder Balls After Reflow.